Study on the water-based conductive anticorrosive coating by adding graphene applied on the surface of steel bar

-

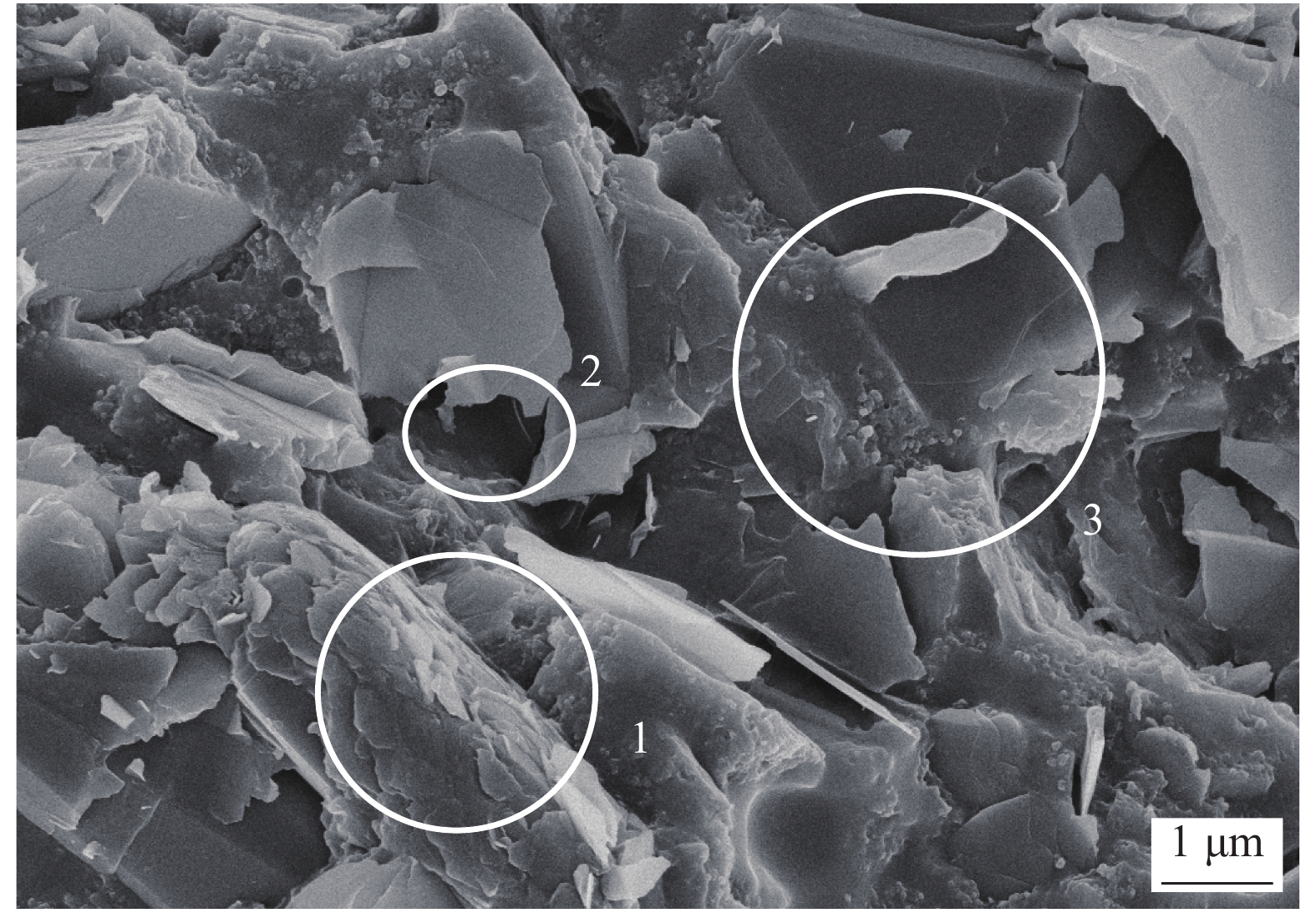

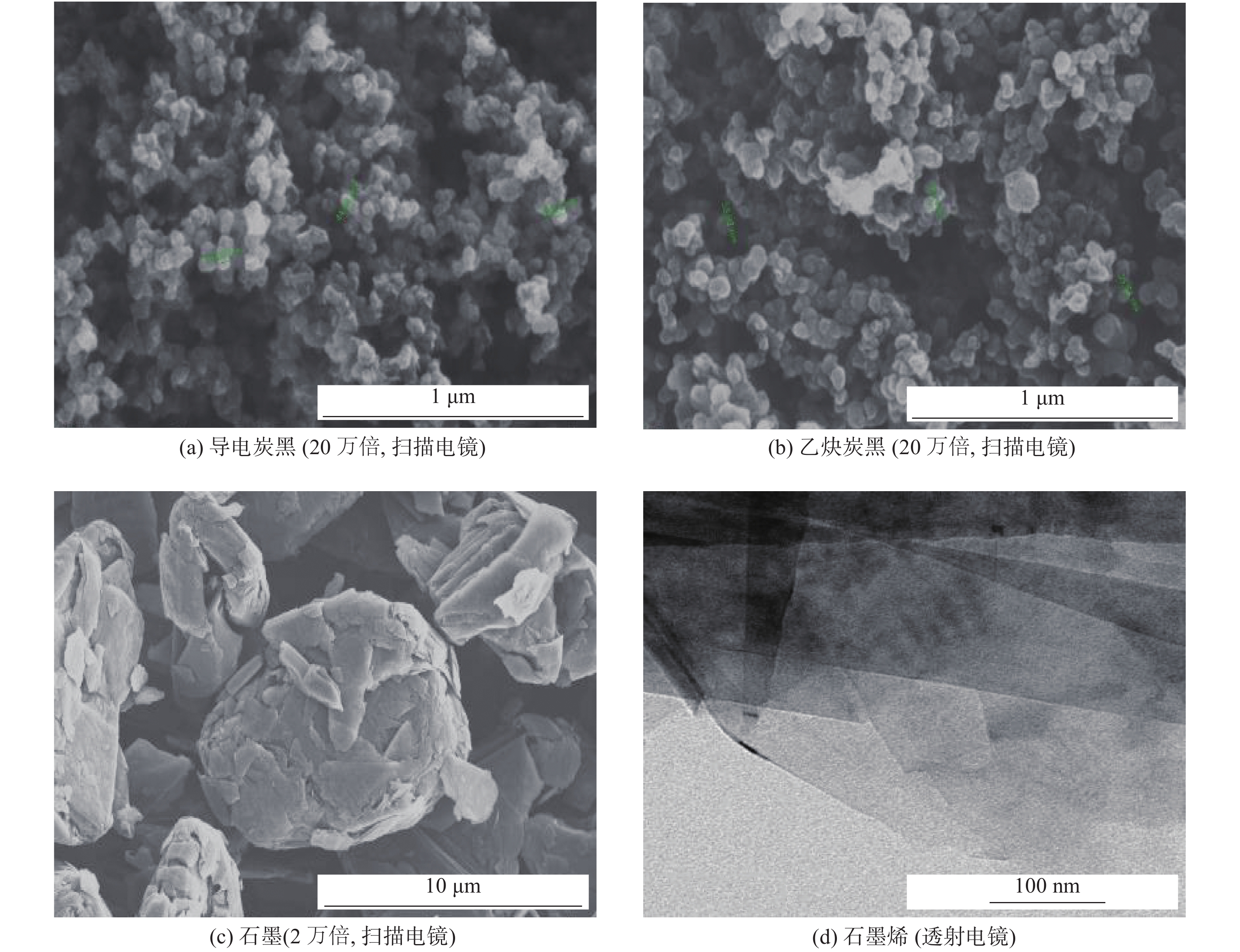

摘要: 作为钢筋混凝土防腐蚀措施的环氧涂层钢筋,在结构运行维护时,由于环氧涂层的绝缘特性而不能采用电化学保护措施。为解决这个问题,利用石墨烯纳米材料具有导电、防腐蚀、抗冲击等特性,以水性环氧树脂为主要成膜物质,掺石墨烯材料和其他导电填料研制得到导电防腐蚀涂料。用电镜表征导电填料的形状和涂层的结构,分析了涂层的导电和防腐蚀作用机制,并测试了导电涂层钢筋与混凝土的粘接性能、耐阴极剥离性能和抗弯性能。试验结果表明:涂层导电性能可达到方块电阻值3 000 Ω/sq以下,涂层耐碱溶液浸泡,在碱性含Cl−溶液中21 d以上涂层不起泡、不生锈,在中性Cl−溶液中21 d以上不起泡、14 d不生锈。石墨烯与其他导电填料混掺才能得到导电性和防腐蚀性能优异的涂层,作用原理是通过薄片状石墨烯、片状石墨和球状炭黑颗粒之间的相互接触传导电子进行导电,利用石墨烯的薄片特点延长介质的渗透通道从而提升涂层的防腐蚀性能。涂层钢筋与混凝土的粘接强度比无涂层钢筋的强度降低约15%,符合国家标准GB/T 25826—2010的要求。Abstract: Epoxy coated reinforcement is one of the anti-corrosion measures for reinforced concrete. Due to the insulation characteristics of epoxy coating, electrochemical protection measures can not be used in the later maintenance of reinforced concrete structure, but this problem may be solved by using conductive anti-corrosion coating on the surface of reinforcement.

Graphene has special properties of conductivity, corrosion resistance and impact resistance. In this paper, a conductive anticorrosive coating composed of water-based epoxy resin, graphene and other conductive fillers is studied. The shape of the conductive filler and the structure of the coating are characterized by electron microscope. The acting mechanisms of conductive and anticorrosive of the coating are analyzed, and the adhesion strength to concrete of the conductive coated reinforcement is tested. The results show that the conductivity of the coating can be less than the square resistance value of 3000 Ω/sq. The coating is alkali resistant while soaked in alkaline solution, and the coating does not blister or rust for more than 21 days in alkaline solution containing Cl−, and does not blister for more than 21 days and does not rust for 14 days in Cl− solution. The coating must be obtained by mixing different conductive fillers including graphene. The conductive mechanism may be that conducts electricity is obtained through the mutual contact among film graphene, flake graphite and spherical carbon black particles. The corrosion resistance of the coating is improved by using the film characteristics of graphene to extend the permeability channel of the medium. The bond strength of coated steel to concrete is about 15% lower than that of uncoated steel, and the result meets the requirements of national standard GB/T 25826—2010. -

Keywords:

- coating /

- reinforcement /

- concrete /

- graphene /

- epoxy resin /

- conductive coating /

- anti-corrosion

-

表 1 分散剂对石墨烯分散的影响

Table 1 Effect of dispersant on dispersion of graphene

分散剂 石墨烯质量浓度/(mg·mL−1) 分散情况 FS-1 5 石墨烯在分散液中悬浊,存在少量颗粒在杯壁附着,静置2 d后几乎完全沉淀。 FS-2 4 石墨烯在分散液中分布均匀,多余石墨烯在液面悬浮,静置2 d后部分沉淀,上清液中仍有微量絮状物。 FS-3 9 石墨烯在分散液中分布均匀,多余石墨烯在液面悬浮,静置2 d后沉淀较少。 表 2 正交试验电导率统计

Table 2 Conductivity statistical table of orthogonal test

各水平平均值 电导率/(S·m−1) 石墨烯 导电炭黑 乙炔炭黑 石墨 K1 27.5 4.8 12.4 30.0 K2 22.3 14.6 38.5 32.7 K3 39.9 23.0 33.3 42.4 K4 40.9 54.3 37.8 39.0 K5 44.2 78.0 52.8 30.8 极差 21.9 73.2 40.4 12.4 表 3 导电填料对涂层的防腐蚀性能的影响

Table 3 Effect of conductive fillers on corrosion resistance of coating

涂层填料含量/% 电阻/(Ω·sq −1) 开始起泡时间/d 开始生锈时间/d 石墨烯 导电炭黑 乙炔炭黑 石墨 碱溶液 碱含Cl−溶液 含Cl−溶液 碱溶液 碱含Cl−溶液 含Cl−溶液 0 0 0 0 >106 >21 21 14 >21 >21 7 4.0 37.0 18.5 60.0 181 >21 14 21 >21 21 7 4.0 12.5 0 60.0 805 >21 >21 >21 >21 >21 14 4.0 0 15.0 60.0 471 >21 >21 >21 >21 21 7 4.0 24.7 11.1 60.0 130 >21 21 21 >21 21 7 4.0 50.0 12.0 20.0 130 7 21 14 >21 21 7 3.0 12.5 15.0 20.0 348 >21 7 14 >21 21 14 3.0 25.0 0 30.0 1 302 >21 >21 >21 >21 21 7 0.5 25.0 9.0 20.0 234 14 7 14 >21 21 7 0.5 50.0 15.0 40.0 126 14 >21 21 >21 21 7 表 4 掺石墨烯导电防腐蚀涂料配方

Table 4 Formulation of conductive anticorrosive coating by adding graphene

A组分 B组分 原材料 质量/g 原材料 质量/g 环氧树脂乳液 18.0~32.0 固化剂 70.0~79.0 增韧剂 0.5~2.0 缓蚀剂 0.5~4.5 石墨烯浆料 21.0~30.0 水 2.5~29.0 导电填料浆料 34.0~45.0 助剂 0.3~3.3 表 5 涂层钢筋与混凝土的粘接强度

Table 5 Bonding strength of coated steel bar to concrete

钢筋涂层种类 特定滑移量对应荷载/kN 破坏时荷载/kN 粘接强度/MPa 相对于无涂层钢筋的百分比/% 0.01 mm 0.05 mm 0.10 mm 无涂层 63 90 104 132.0 12.99 − A0涂层 30 68 86 92.0 9.30 71.6 AG涂层 49 77 91 114.0 10.97 84.4 AGC涂层 51 73 95 106.7 11.07 85.2 注:A0为未添加导电填料,AG为添加石墨烯,AGC为添加石墨烯和导电炭黑。 -

[1] 潘琪, 苏和. 环氧树脂涂层钢筋在南麂码头工程中的应用[J]. 交通世界,2017(20):156-157, 160. (PAN Qi, SU He. Application of epoxy resin coated steel bars in Nanji wharf project[J]. Transpoworld, 2017(20): 156-157, 160. (in Chinese) [2] 程致高, 宋华清, 孙士辉. 环氧钢筋在金塘大桥中的应用[J]. 公路,2009(1):209-212. (CHENG Zhigao, SONG Huaqing, SUN Shihui. Application of epoxy resin coated reinforcement in Jintang bridge[J]. Highway, 2009(1): 209-212. (in Chinese) [3] 中国科学院金属研究所. 港珠澳大桥通车, 金属所耐久性技术保护超级工程[EB/OL]. [2018-10-24]. http://www.ecorr.org/dhTJDAOHANG/cjzl/yejiedongtai/2018-10-24/170782.html. Institute of Metal Research, Chinese Academy of Sciences. Hong Kong Zhuhai Macao bridge opened to traffic, super project of durability technical protection of metal institute[EB/OL]. [2018-10-24]. http://www.ecorr.org/dhTJDAOHANG/cjzl/yejiedongtai/2018-10-24/170782.html. (in Chinese)

[4] 刘新福. 锌加涂层在高铁桥梁下部结构钢筋防腐中的应用[J]. 铁道建筑技术,2012(8):1-3, 40. (LIU Xinfu. Application of zinga in anti-corrosion of substructure steel bar in bridges on high-speed railway[J]. Railway Construction Technology, 2012(8): 1-3, 40. (in Chinese) doi: 10.3969/j.issn.1009-4539.2012.08.001 [5] 王弯弯, 张胜寒, 张秀丽, 等. 沿海及盐渍地区输电杆塔混凝土钢筋阴极保护技术研究[J]. 华北电力技术,2016(8):13-17. (WANG Wanwan, ZHANG Shenghan, ZHANG Xiuli, et al. Research on cathodic protection of reinforced concrete transmission tower in salinization and coastal areas[J]. North China Electric Power, 2016(8): 13-17. (in Chinese) [6] 朱宇光. 本征型与添加型导静电防腐涂料的性能对比和应用[J]. 上海涂料,2010,48(9):19-21. (ZHU Yuguang. Performance comparison and application of intrinsic type and additional type antistatic anticorrosion paint[J]. Shanghai Coatings, 2010, 48(9): 19-21. (in Chinese) doi: 10.3969/j.issn.1009-1696.2010.09.006 [7] 梁永纯, 杜春苹, 王伟, 等. 导电涂料研究现状及其应用[J]. 广东电力,2012,25(3):1-4, 30. (LIANG Yongchun, DU Chunping, WANG Wei, et al. Research status of conducting paint and its application[J]. Guangdong Electric Power, 2012, 25(3): 1-4, 30. (in Chinese) doi: 10.3969/j.issn.1007-290X.2012.03.001 [8] 罗健, 王继虎, 温绍国, 等. 石墨烯在防腐涂料中的研究进展[J]. 涂料工业,2017,47(11):69-76. (LUO Jian, WANG Jihu, WEN Shaoguo, et al. Research progress in graphene for anticorrosive coatings[J]. Paint & Coatings Industry, 2017, 47(11): 69-76. (in Chinese) [9] 孟晓明, 楼平, 赵永生, 等. 碳纳米管、石墨烯在导电涂料中的应用研究进展[J]. 涂料工业,2015,45(5):82-87. (MENG Xiaoming, LOU Ping, ZHAO Yongsheng, et al. Progress in application of carbon nanotubes and graphene in conductive coatings[J]. Paint & Coatings Industry, 2015, 45(5): 82-87. (in Chinese) doi: 10.3969/j.issn.0253-4312.2015.05.018 [10] 钟涛. 水性金属防腐蚀涂料的研制及功能化[D]. 扬州: 扬州大学, 2012. ZHONG Tao. Development and functionalization of waterborne anticorrosive coatings for metals[D]. Yangzhou: Yangzhou University, 2012. (in Chinese)

Email Alerts

Email Alerts RSS

RSS

下载:

下载: