Study on bearing mechanism of grouting prestressed lining structure of water conveyance tunnel

-

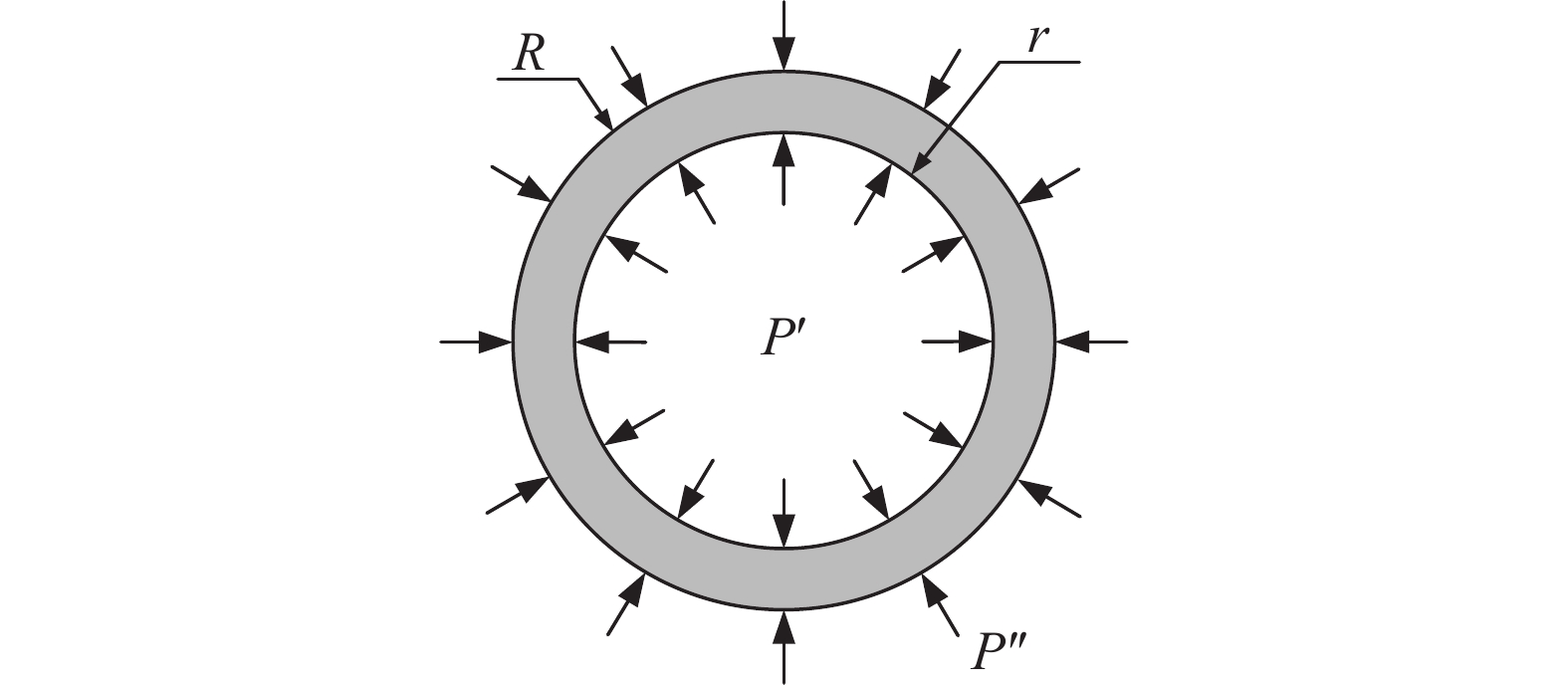

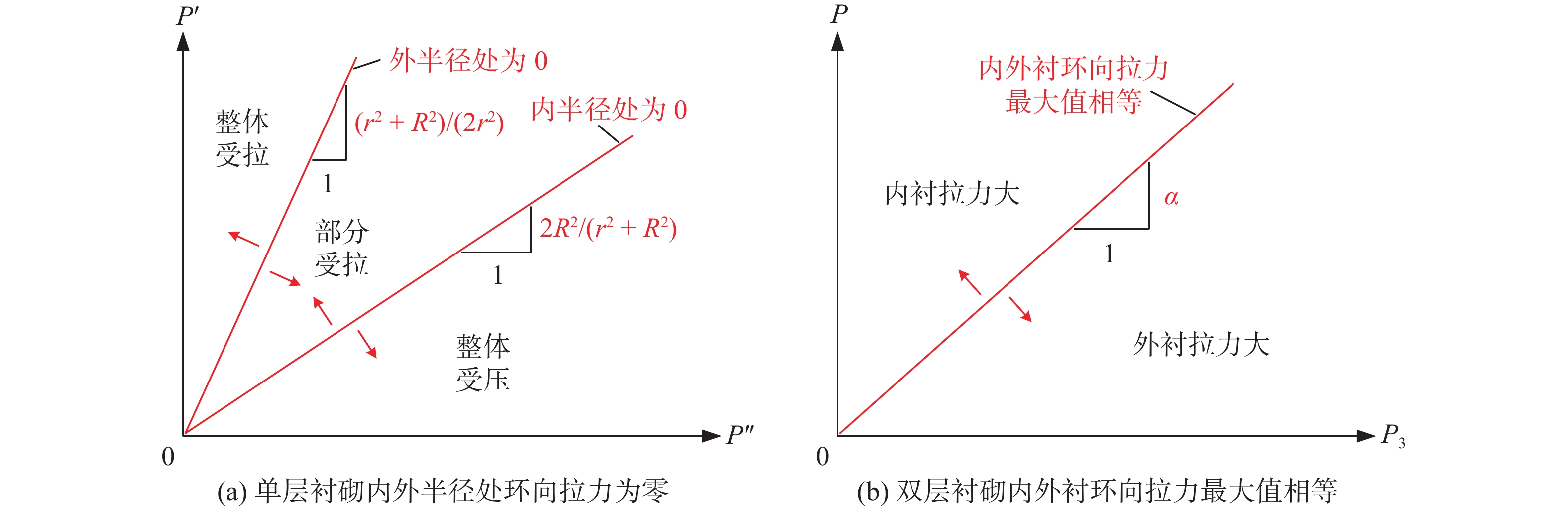

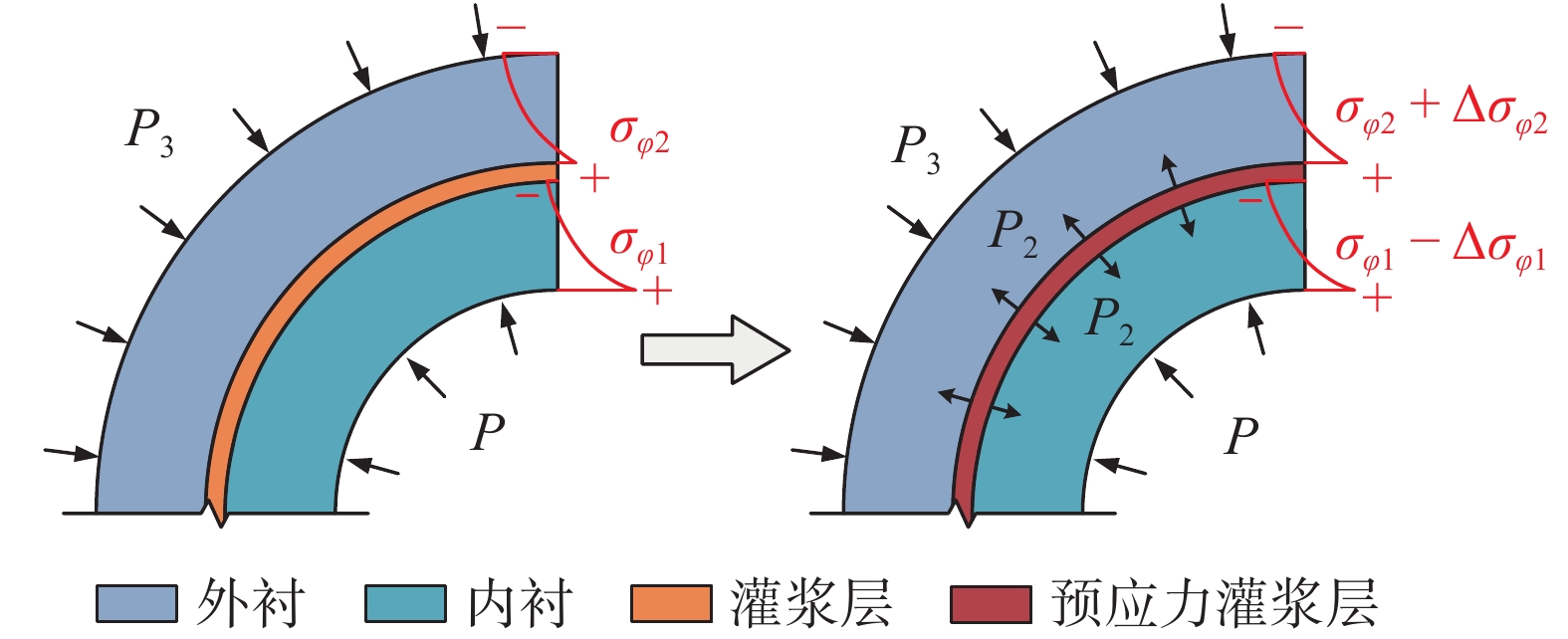

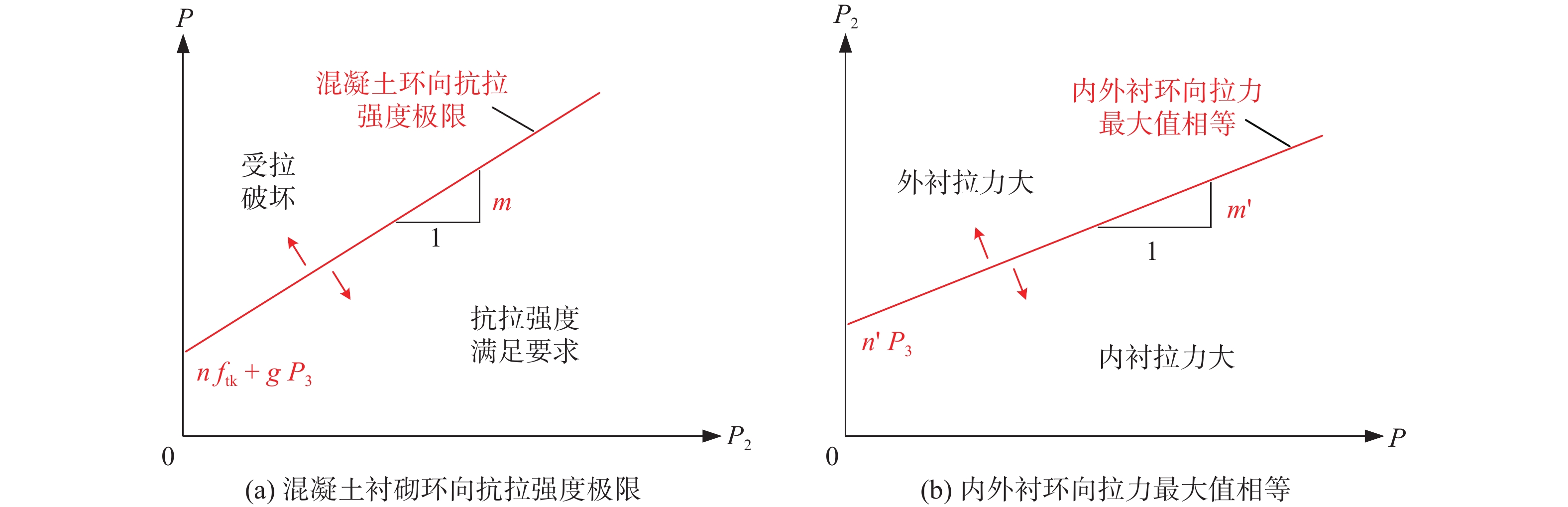

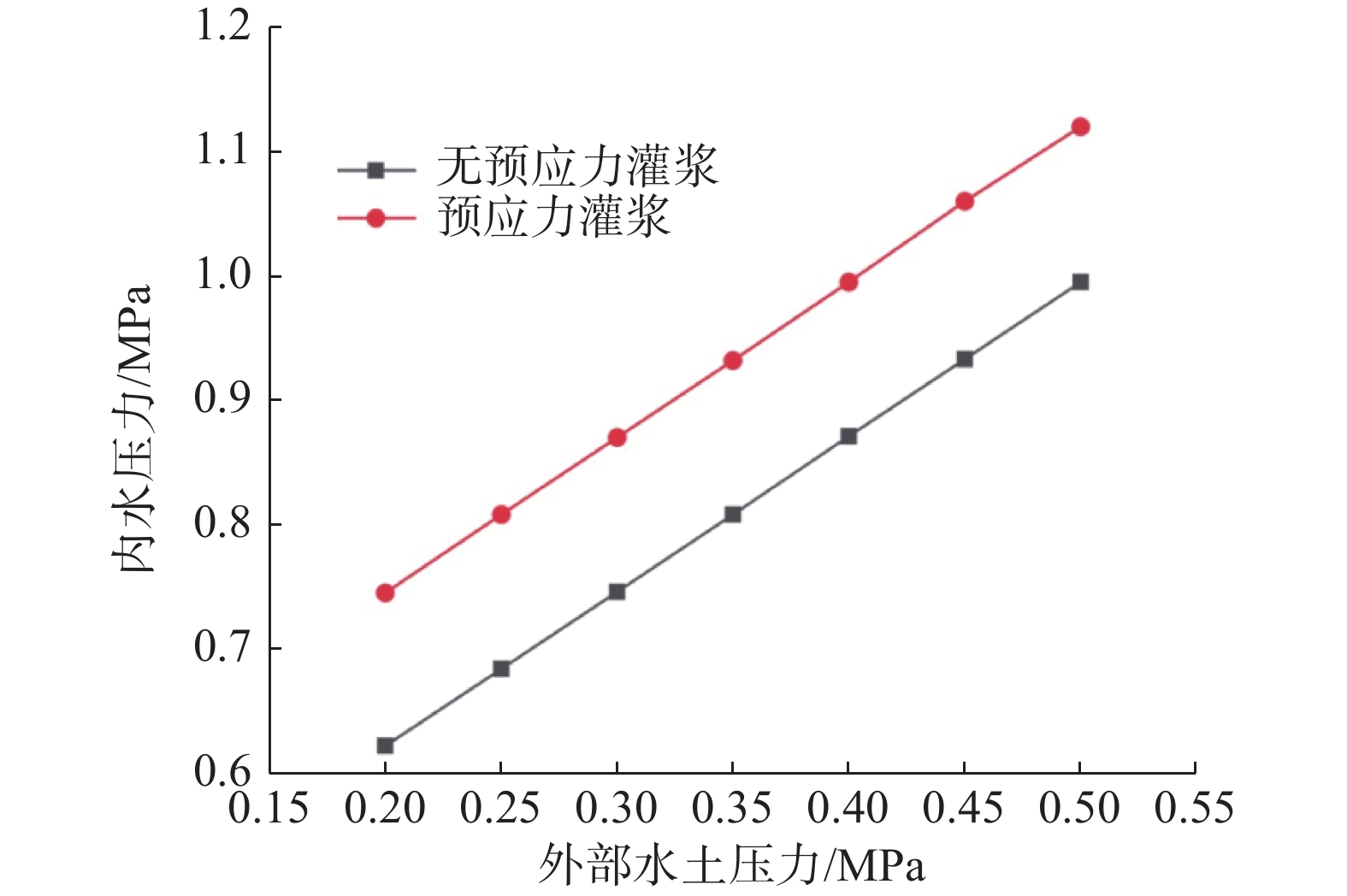

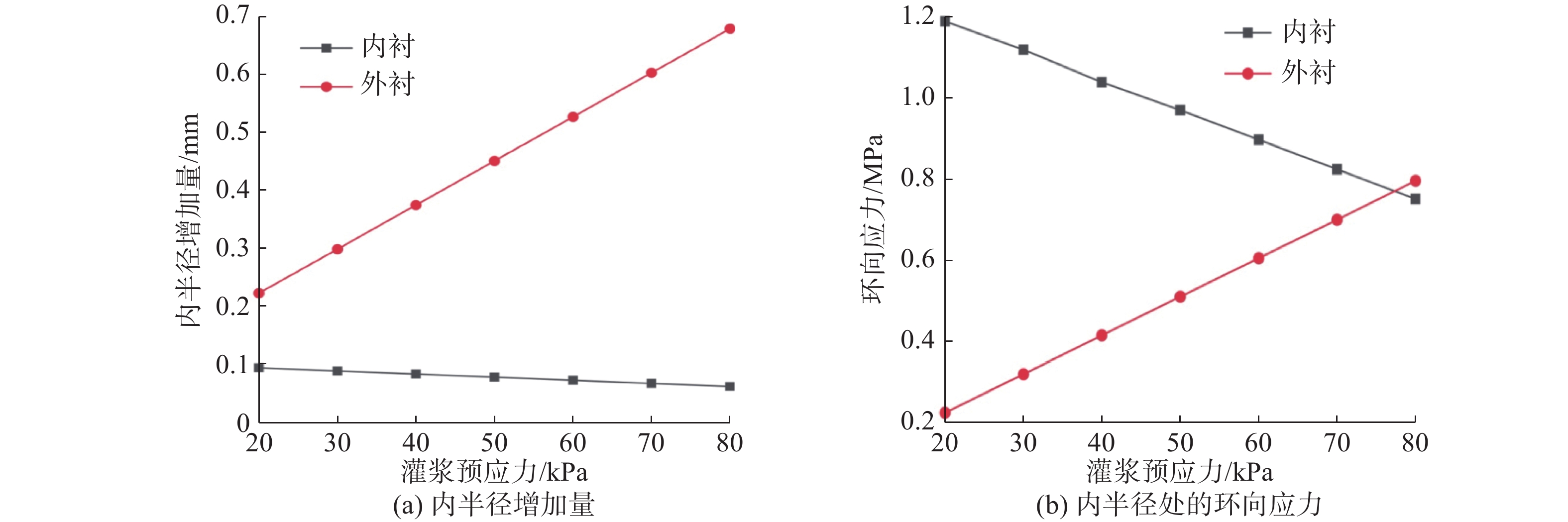

摘要: 输水隧洞双层混凝土衬砌之间采用预应力灌浆可以提高结构的承载能力,但此类灌浆式预应力衬砌结构的承载机理尚未得到系统阐释。基于弹性理论,采用荷载结构法,建立了考虑变形协调关系的灌浆式预应力衬砌力学分析模型。通过对衬砌结构的受力分析,揭示了预应力灌浆提高衬砌结构承载力的机理,推演了衬砌结构环向拉应力判定式,以及环向抗拉强度与灌浆预应力的关系式。利用有限元数值模拟验证了理论方法的合理性,针对工程案例分析了灌浆预应力对衬砌结构的定量影响规律。结果表明:结构能承担的最大内水压力与灌浆预应力及外部水土压力,均近似呈线性正相关,内衬结构的径向变形和环向应力随灌浆预应力的增大而减小,外衬结构的径向变形和环向应力随灌浆预应力增大而显著增大。这种考虑临界情况的分析和计算方法,揭示了灌浆式预应力衬砌结构的承载机理,可为该类型输水隧洞的力学分析和结构设计提供理论依据。Abstract: Prestressed grouting between double-layer concrete linings of water conveyance tunnel can improve the bearing capacity of the structure, but the bearing mechanism of this kind of grouting prestressed lining structure has not been systematically explained. Based on the elastic theory, the mechanical analysis model of grouted prestressed lining considering the deformation coordination relationship is established by using the load structure method. Through the stress analysis of lining structure, the mechanism of prestressed grouting to improve the bearing capacity of lining structure is revealed, and the judgment formula of circumferential tensile stress of lining structure and the relationship between circumferential tensile strength and grouting prestress are deduced. The rationality of the theoretical method is verified by finite element numerical simulation, and the quantitative influence law of grouting prestress on lining structure is analyzed according to engineering cases. It is found that the maximum internal water pressure that the structure can bear is approximately linearly positively correlated with the grouting prestress and external water and soil pressure. The radial deformation and circumferential stress of the inner lining structure decrease with the increase of grouting prestress, while the radial deformation and circumferential stress of the outer lining structure significantly increase with the increase of grouting prestress. This analysis and calculation method considering critical conditions reveals the bearing mechanism of grouting prestressed lining structure, which can provide a theoretical basis for the mechanical analysis and structural design of this type of water conveyance tunnel.

-

-

表 1 模型计算参数

Table 1 Model calculation parameters

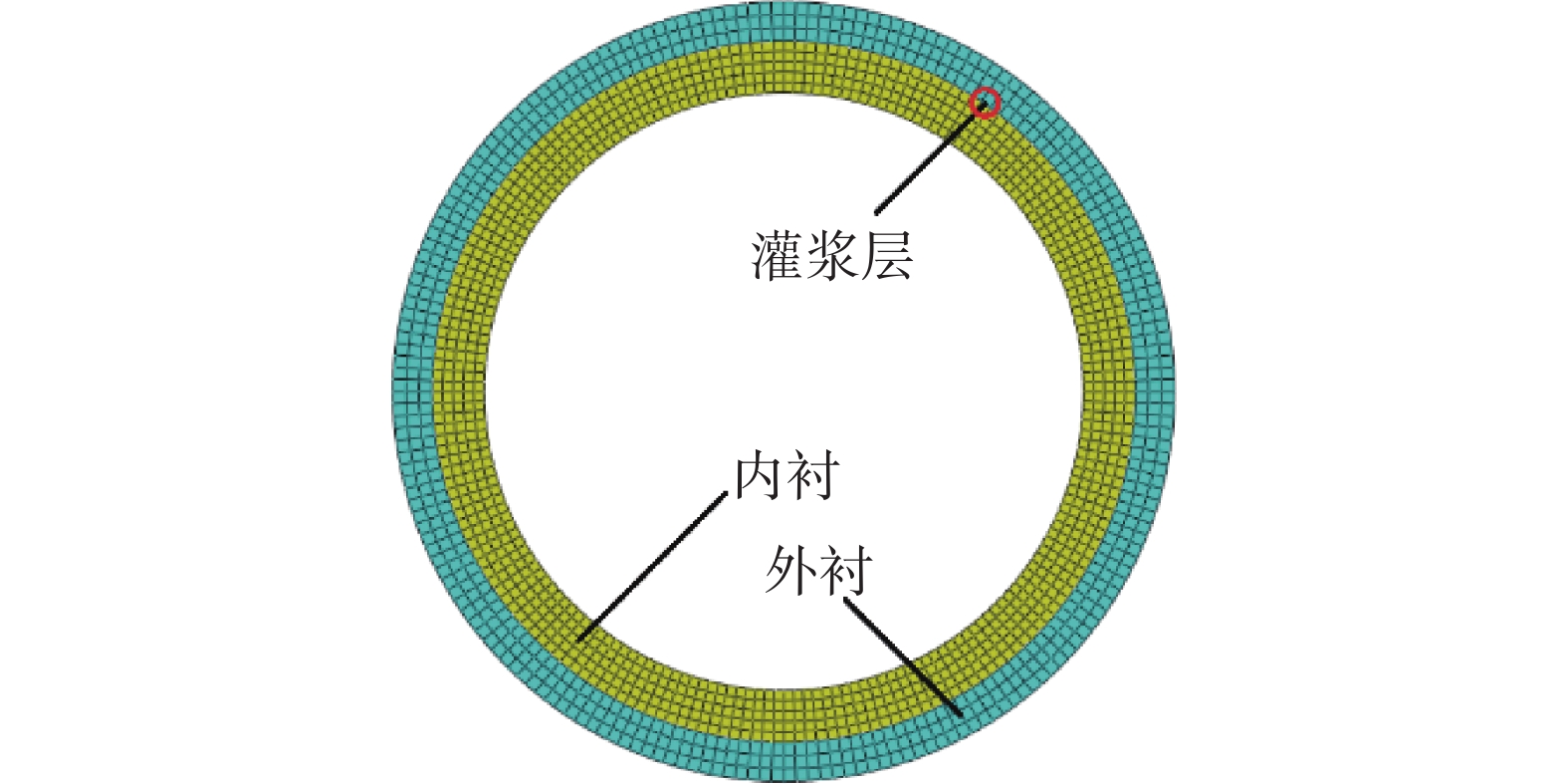

材料 E/MPa μ r/m R/m 外衬(C50) 3.45×103 0.17 2.700 0 3.000 0 灌浆层(凝固后) 20.00 0.30 2.698 5 2.700 0 内衬(C35) 3.15×104 0.17 2.300 0 2.698 5 表 2 衬砌环向应力的数值分析与解析计算结果

Table 2 Numerical analysis and analytical calculation results of circumferential stress of lining

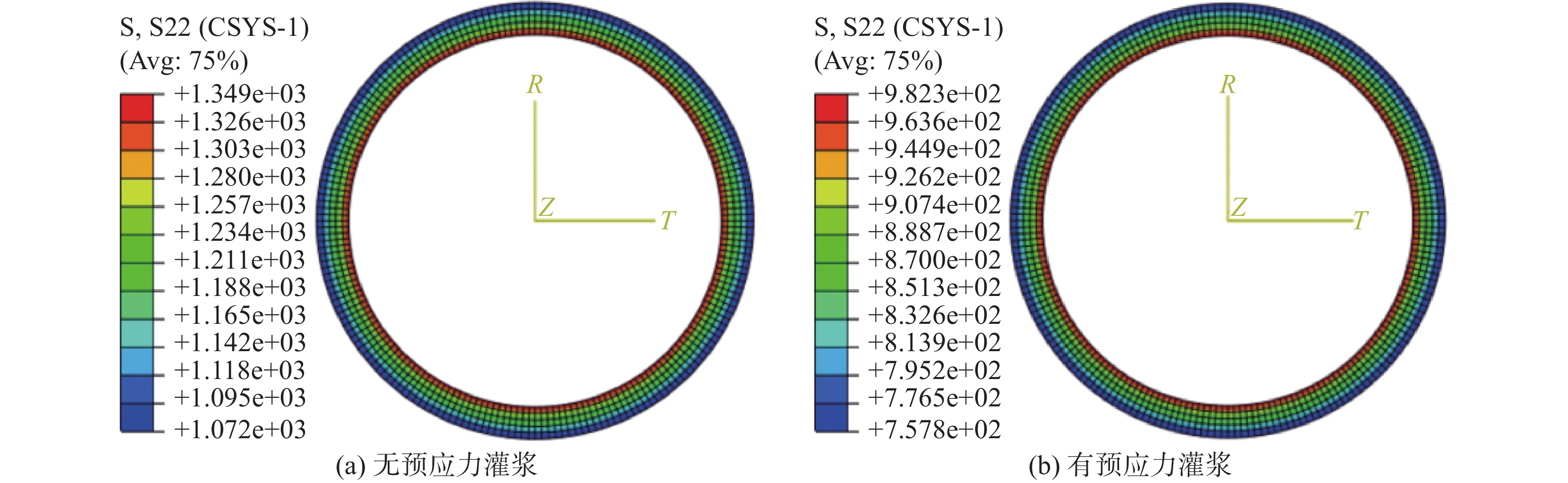

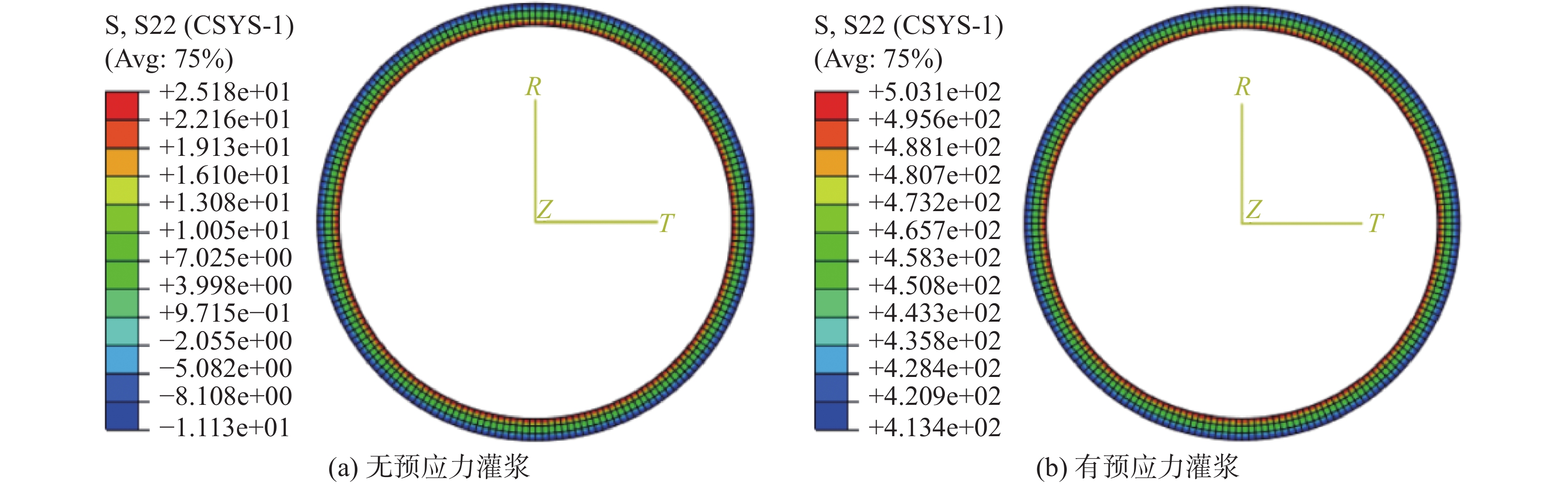

单位:MPa 分析位置 无预应力 有预应力 数值分析 解析计算 数值分析 解析计算 內衬内半径 1.35 1.34 0.982 0.971 外衬内半径 2.52×10-2 3.45×10-2 0.503 0.511 -

[1] 曹生荣, 杨帆, 秦敢, 等. 盾构输水隧洞设垫层预应力复合衬砌承载特性研究[J]. 水力发电学报,2015,34(2):136-143 CAO Shengrong, YANG Fan, QIN Gan, et al. Study on bearing behavior of prestressed composite linings with cushion layer for water conveyance shield tunnel[J]. Journal of Hydroelectric Engineering, 2015, 34(2): 136-143. (in Chinese)

[2] CHEN Y, WANG Y Z, ZHANG Q Y. Coupled seepage-elastoplastic-damage analysis of saturated porous media and its application to water conveyance tunnel[J]. Tunnelling and Underground Space Technology, 2014, 44: 80-87. doi: 10.1016/j.tust.2014.07.007

[3] YANG F, CAO S R, QIN G. Performance of the prestressed composite lining of a tunnel: case study of the Yellow River crossing tunnel[J]. International Journal of Civil Engineering, 2018, 16(2): 229-241. doi: 10.1007/s40999-016-0124-0

[4] 邹志林. 海底取水盾构隧道双层衬砌结构受力特性研究[D]. 长沙: 中南大学, 2013. ZOU Zhilin. Study of mechanical characters of subsea water-intaken shield tunnel with double lining[D]. Changsha: Central South University, 2013. (in Chinese)

[5] 阳军生, 肖小文, 张聪, 等. 盾构隧道双层衬砌结构受力现场监测试验研究[J]. 铁道工程学报,2016,33(7):46-53 YANG Junsheng, XIAO Xiaowen, ZHANG Cong, et al. Experimental research on the site monitoring of double lining structure in shield tunnel[J]. Journal of Railway Engineering Society, 2016, 33(7): 46-53. (in Chinese)

[6] 杨钊, 潘晓明, 余俊. 盾构输水隧洞复合衬砌计算模型[J]. 中南大学学报(自然科学版),2010,41(5):1945-1952 YANG Zhao, PAN Xiaoming, YU Jun. Calculation model on double linings of water diversion shield tunnel[J]. Journal of Central South University (Science and Technology), 2010, 41(5): 1945-1952. (in Chinese)

[7] 杨光华, 李志云, 徐传堡, 等. 盾构隧洞复合衬砌的荷载结构共同作用模型[J]. 水力发电学报,2018,37(10):20-30 YANG Guanghua, LI Zhiyun, XU Chuanbao, et al. Modeling load-structure interaction in shield tunnel composite lining[J]. Journal of Hydroelectric Engineering, 2018, 37(10): 20-30. (in Chinese)

[8] 赵长海. 灌浆式预应力混凝土衬砌隧洞[J]. 水利水电技术,1999,30(12):65-69 ZHAO Changhai. Grouted prestressed concrete lining tunnel[J]. Water Resources and Hydropower Engineering, 1999, 30(12): 65-69. (in Chinese)

[9] 丁艳辉, 付云升, 杨进新, 等. 盾构输水隧洞灌浆式预应力衬砌结构有限元分析[J]. 水利水电技术,2018,49(7):103-108 DING Yanhui, FU Yunsheng, YANG Jinxin, et al. Finite element analysis on pre-stressed grouted concrete lining of water conveyance tunnel constructed by shield tunneling method[J]. Water Resources and Hydropower Engineering, 2018, 49(7): 103-108. (in Chinese)

[10] 皮进, 曹瑞琅, 王玉杰, 等. 不同断面形状的无粘结环锚衬砌应力状态分析[J]. 地下空间与工程学报,2018,14(增刊2):667-672 PI Jin, CAO Ruilang, WANG Yujie, et al. Stress state analysis of different cross-section shape pre-stressed concrete lining with un-bonded annular anchors[J]. Chinese Journal of Underground Space and Engineering, 2018, 14(Suppl2): 667-672. (in Chinese)

[11] 曹瑞琅, 王玉杰, 汪小刚, 等. 无黏结预应力环锚衬砌力学特性原位加载试验研究[J]. 岩土工程学报,2019,41(8):1522-1529 CAO Ruilang, WANG Yujie, WANG Xiaogang, et al. Mechanical properties of pre-stressed linings with un-bonded annular anchors under high internal water pressure based on large-scale in situ tests[J]. Chinese Journal of Geotechnical Engineering, 2019, 41(8): 1522-1529. (in Chinese)

[12] 亢景付, 沈兆伟, 荆锐, 等. 环锚预应力混凝土衬砌锚具槽区域应力状态分析[J]. 水电能源科学,2016,34(7):108-111 KANG Jingfu, SHEN Zhaowei, JING Rui, et al. Stress state analysis of anchorage slot area of pre-stressed concrete lining[J]. Water Resources and Power, 2016, 34(7): 108-111. (in Chinese)

[13] 沈来新, 付云升. 盾构输水隧洞预应力钢筋混凝土衬砌结构设计研究[J]. 水利水电技术,2013,44(7):73-76 SHEN Laixin, FU Yunsheng. Design and study of pre-stress reinforced concrete lining structure for shield-water conveyance tunnel[J]. Water Resources and Hydropower Engineering, 2013, 44(7): 73-76. (in Chinese)

[14] SIMANJUNTAK T D Y F, MARENCE M, MYNETT A E, et al. Pressure tunnels in non-uniform in situ stress conditions[J]. Tunnelling and Underground Space Technology, 2014, 42: 227-236. doi: 10.1016/j.tust.2014.03.006

[15] ANDJELKOVIC V, LAZAREVIC Z, NEDOVIC V, et al. Application of the pressure grouting in the hydraulic tunnels[J]. Tunnelling and Underground Space Technology, 2013, 37: 165-179. doi: 10.1016/j.tust.2012.08.012

[16] 刘成, 汤昕怡, 高玉峰. 砂性地层孔隙特征对泥水盾构泥浆成膜的影响[J]. 岩土工程学报,2017,39(11):2002-2008 LIU Cheng, TANG Xinyi, GAO Yufeng. Influence of pore characteristics of sand strata on filter-cake formation under slurry shield[J]. Chinese Journal of Geotechnical Engineering, 2017, 39(11): 2002-2008. (in Chinese)

[17] 刘成, 陆杨, 吕伟华, 等. 砂性地层中盾构泥浆粗粒材料对成膜效果的影响[J]. 中国公路学报,2018,31(9):104-111 LIU Cheng, LU Yang, LÜ Weihua, et al. Effects of coarse-particle materials in slurry on filter-cake formation effectiveness in sandy strata[J]. China Journal of Highway and Transport, 2018, 31(9): 104-111. (in Chinese)

[18] 王俊, 徐国文, 蔚艳庆, 等. 一种改进的盾构隧道双层衬砌计算模型及其工程应用[J]. 岩土工程学报,2021,43(8):1502-1510 WANG Jun, XU Guowen, WEI Yanqing, et al. An improved model for shield tunnels with double-layer linings and its application in engineering[J]. Chinese Journal of Geotechnical Engineering, 2021, 43(8): 1502-1510. (in Chinese)

[19] 陈秋杰, 杨仲轩, 徐荣桥, 等. 一种新的盾构隧道双层衬砌解析分析方法[J]. 岩石力学与工程学报,2020,39(增刊1):2713-2724 CHEN Qiujie, YANG Zhongxuan, XU Rongqiao, et al. A new analytical solution for shield tunnel with double lining[J]. Chinese Journal of Rock Mechanics and Engineering, 2020, 39(Suppl1): 2713-2724. (in Chinese)

[20] 彭亚敏, 沈振中, 甘磊. 深埋水工隧洞衬砌渗透压力控制措施研究[J]. 水利水运工程学报,2018(1):89-94 PENG Yamin, SHEN Zhenzhong, GAN Lei. Seepage pressure control measures for lining of deep buried hydraulic tunnels[J]. Hydro-Science and Engineering, 2018(1): 89-94. (in Chinese)

[21] 肖欣宏, 王静, 谢小帅, 等. 复杂岩溶地区引水隧洞衬砌外水压力研究[J]. 水利水运工程学报,2018(5):82-88 XIAO Xinhong, WANG Jing, XIE Xiaoshuai, et al. External water pressure on diversion tunnel lining in complex Karst area[J]. Hydro-Science and Engineering, 2018(5): 82-88. (in Chinese)

[22] 张冬梅, 周文鼎, 卜祥洪, 等. 盾构-钢筋钢纤维混凝土双层衬砌内水压下破坏机理试验研究[J]. 岩土工程学报, 2022, 44(8): 1528-1534. ZHANG Dongmei, ZHOU Wending, BU Xianghong, et al. Experimental study on failure mechanism of shield-steel fiber reinforced concrete double lining under internal water pressure[J]. Chinese Journal of Geotechnical Engineering, 2022, 44(8): 1528-1534. (in Chinese)

[23] 何灏典, 唐欣薇, 严振瑞, 等. 复合式衬砌结构联合承载的原位试验与数值分析[J]. 岩土工程学报,2022,44(3):560-568 HE Haodian, TANG Xinwei, YAN Zhenrui, et al. In-situ tests and numerical analysis of composite lining structures with joint bearing[J]. Chinese Journal of Geotechnical Engineering, 2022, 44(3): 560-568. (in Chinese)

[24] 姚家晨, 杨建喜, 曾东, 等. 考虑环间接头力学特性的盾构隧洞纵向分析模型[J]. 水利水运工程学报, 2022(4):114-122. YAO Jiachen, YANG Jianxi, ZENG Dong, et al. Longitudinal analysis model of shield tunnel considering mechanical characteristics of ring joint[J]. Hydro-Science and Engineering, 2022(4):114-122. (in Chinese)

Email Alerts

Email Alerts RSS

RSS

下载:

下载: